5 trends shaping industrial asset tracking in 2025

Share this article

Contents

Share this article

1. Widespread use of predictive maintenance: towards a drastic reduction in downtime

In an industrial context where continuity of operations is strategic, predictive maintenance is one of the most structuring pillars of asset tracking trends in 2025. It is no longer a niche innovation, but a core function, now natively integrated into the most advanced asset tracking platforms.

This evolution is directly driven by the combined rise of industrial IoT, edge computing and embedded artificial intelligence. Today, every critical asset - whether a piece of production equipment, an automated forklift truck or a storage system - becomes a continuous source of data. Temperature, vibrations, intensity of use, load cycles: all these parameters are analyzed in real time to detect the first weak signals of failure.

The challenge is no longer simply to "repair faster", but toanticipate breakdowns before they impact the value chain. By coupling maintenance histories with predictive models, manufacturers can plan interventions at the optimum time, avoid unplanned stoppages and significantly extend the life of assets.

The return on investment is tangible: reduced corrective maintenance costs, increased equipment availability, lower scrap rates and enhanced reliability. In capital-intensive sectors such as aeronautics, automotive and food production, predictive maintenance is becoming a performance standard.

More broadly, it is part of a dynamic of digital transformation of the asset lifecycle, where tracking is no longer limited to knowing "where the equipment is", but extends to a detailed understanding of "how it behaves and when it will fail". For maintenance and industrial managers, this evolution represents a paradigm shift in both operations and culture.

2. Artificial intelligence and analytics: asset tracking becomes a decision-making tool

In the industrial landscape of 2025,artificial intelligence (AI) is no longer limited to a complementary analysis function: it is becoming a strategic building block for asset management. Coupled with data from geolocation, IoT sensors and information systems, AI transformsasset tracking platforms into autonomous decision-making tools, capable of understanding context, detecting anomalies and acting accordingly.

Among the most structuring asset tracking trends, this advanced analysis capability, enabled by supervised and unsupervised machine learning, occupies a central place. It enables systems to "understand" normal asset behavior (usage patterns, movement rhythms, environmental interactions) and identify any drift, be it overheating, abnormal movement, prolonged immobilization or logistical deviation.

These analytic functions feed into concrete, automated actions: dynamic repositioning of an asset, triggering conditional maintenance, sending a contextual alert to an operator, or even reconfiguring a logistics flow according to actual equipment availability.

But the impact doesn't stop at local optimization. On the scale of a site or logistics network, these micro-decisions taken on a continuous basis build a distributed operational intelligence, capable of reducing waste (time, energy, surface area), improving responsiveness in the event of a hazard, and reinforcing the resilience of industrial systems.

AI thus paves the way for a paradigm shift in the world of asset tracking: from a "passive" asset tracking system, focused on location, to an asset intelligence system, capable of prioritizing emergencies, proposing arbitrages and, ultimately, integrating into autonomous steering loops.

3. Technological convergence: towards multi-layer, resilient asset tracking

Today, indoor geolocation is one of the most promising trends in industrial asset tracking, but is still far from widespread. Unlike outdoor geolocation, now mature thanks to GPS and cellular networks, precise positioning inside industrial buildings is still a major optimization challenge.

According to a survey conducted by OpinionWay for Wheere in 2024, only 49% of French manufacturers claim to be equipped with at least one geolocation technology on their site. In other words, more than half of industrial players still have no solution enabling them to precisely locate their assets in indoor environments. This finding highlights a largely untapped potential for operational efficiency.

In contexts where time wasted searching for equipment, skips, carts or semi-finished batches can represent up to several hours per day and per operator, the ability to geolocate resources with precision is becoming a key performance factor. Added to this are the growing challenges of traceability, safety, maintenance and man-machine coordination.

While certain technologies such as Ultra Wideband, BLE beacons or sensor fusion are beginning to be deployed, their adoption remains hampered by infrastructure constraints, cost, or integration with existing systems. In this still fragmented landscape, Wheere is positioned as a solution that combines efficiency and ease of installation.

This article may also be of interest to you

The 10 technological innovations revolutionizing Industry 4.0

4. Indoor geolocation: the discreet innovation that is gradually transforming industrial sites

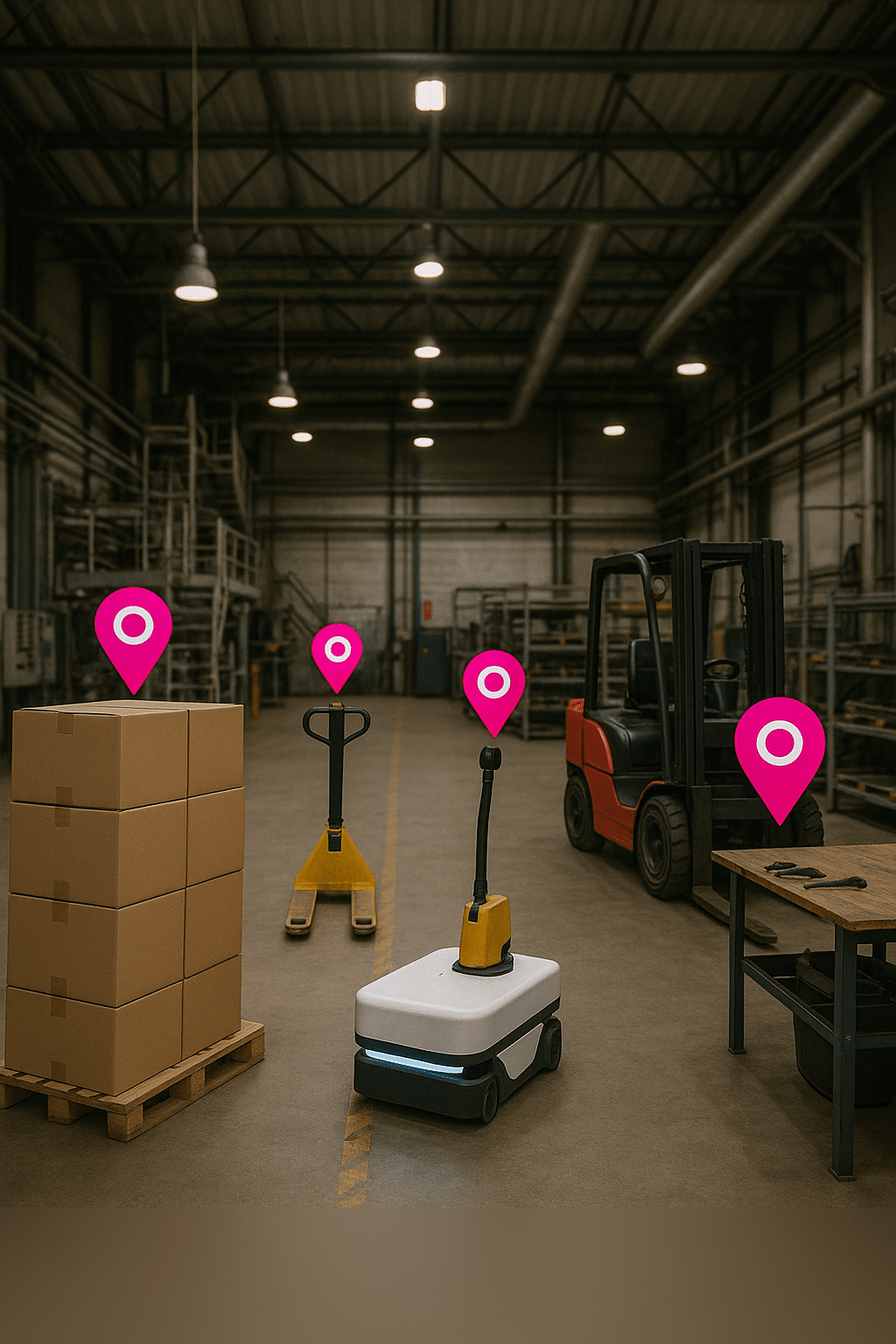

Today, indoor geolocation is one of the most promising trends in industrial asset tracking, but is still far from widespread. Unlike outdoor geolocation, now mature thanks to GPS and cellular networks, precise positioning inside industrial buildings is still a major optimization challenge.

According to a survey conducted by OpinionWay for Wheere in 2024, only 49% of French manufacturers claim to be equipped with at least one geolocation technology on their site. In other words, more than half of industrial players still have no solution enabling them to precisely locate their assets in indoor environments. This finding highlights a largely untapped potential for operational efficiency.

In contexts where time wasted searching for equipment, skips, carts or semi-finished batches can represent up to several hours per day and per operator, the ability to geolocate resources with precision is becoming a key performance factor. Added to this are the growing challenges of traceability, safety, maintenance and man-machine coordination.

While certain technologies such as Ultra Wideband, BLE beacons or sensor fusion are beginning to be deployed, their adoption remains hampered by infrastructure constraints, cost, or integration with existing systems. In this still fragmented landscape, Wheere is positioned as a solution that combines efficiency and ease of installation.

5. Asset security: a critical link in the industrial value chain

In 2025, the security of industrial assets can no longer be dissociated from major asset tracking trends. Long relegated to a secondary concern in geolocation or industrial IoT projects, securing equipment, flows and data is now becoming a sine qua non for large-scale deployment of these technologies.

Faced with growing threats - targeted theft from logistics sites, internal sabotage, hijacking, data falsification and industrial espionage - companies can no longer be satisfied with simple perimeter measures. Asset tracking systems themselves must integrate cybersecurity and access control functions by design.

This evolution is reflected in the widespread use of a number of devices: geofencing to define authorized or prohibited perimeters, automated alerts in the event of non-compliant movement, multi-level user authentication, end-to-end encryption of data flows between sensors and cloud platforms, and secure event logging, essential for auditing and regulatory compliance (particularly in the pharmaceutical, aerospace and defense sectors).

What distinguishes the most advanced approaches in 2025 is the ability of systems to dynamically adapt security levels according to context. For example, a sensitive asset moved outside its normal time slot may trigger a priority alert, while low-criticality equipment can be monitored more flexibly.

Asset tracking trends 2025: towards intelligent, integrated management of industrial operations

In 2025,industrial asset tracking will undergo a profound transformation. It's no longer just a matter of locating equipment, but of finely controlling operations, anticipating hazards, securing flows and optimizing field decisions based on reliable, contextualized data.

The asset tracking trends identified in this article - predictive maintenance, precise indoor geolocation, artificial intelligence, technological convergence and integrated safety - outline the contours of a hybrid, modular and intelligent system, tailored to the real constraints of the industry.

This evolution is neither cosmetic nor speculative: it is already at work in the field, driven by innovative players like Wheere, who are reinventing the technological and operational standards of asset tracking. It does, however, imply a change of attitude on the part of manufacturers: they need to move from an equipment-based approach to one based on theintelligent orchestration of resources, by fully integrating asset tracking into core business processes.

Against a backdrop of tightening supply chains, the quest for energy efficiency, accelerated digitalization and growing demands for traceability, asset tracking is becoming a strategic lever. Companies that anticipate and embrace these trends will enjoy a decisive competitive advantage - not in the distant future, but today.

Did you like it?

Share it and discover other articles you might also like!

- Articles

- News

- News