Industrial automation: the top 5 challenges in the field

Share this article

Contents

Share this article

Challenge 1 - Manage the variability of industrial environments

Automation in industry: the realities on the ground

Industrial automation has long relied on stable, predictable environments, designed to maximize task repeatability. But the reality in the field is very different: order fluctuations, frequent reconfigurations, logistical delays or technical hazards regularly disrupt established flows.

In this context, an automated system that is too rigid quickly becomes a source of bottlenecks. This is one of the major challenges identified by industrial sites seeking to automate while retaining the ability to adapt to day-to-day changes.

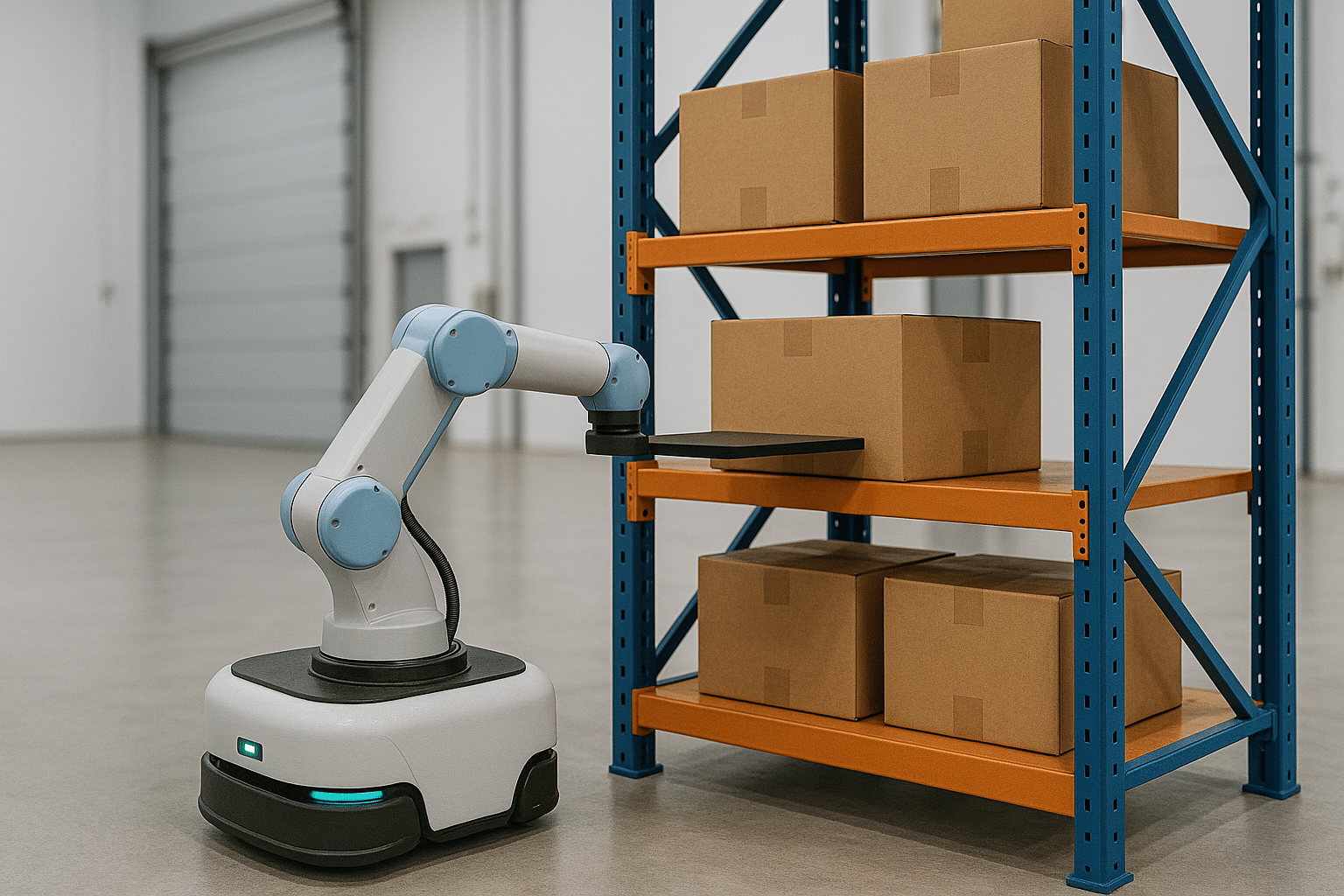

Example: AMR disoriented in a variable environment

At an automotive parts production plant, teams deployed autonomous mobile robots (AMRs) to supply workstations. Initially, these robots followed fixed routes, adapted to a standard logistics configuration.

But as soon as an urgent order requires a temporary rearrangement of bins or stations, the AMRs find themselves in failure: invalid routes, delivery points moved, missions not completed. Result: interrupted flow, queues, loss of speed.

This type of malfunction illustrates the limits of industrial automation designed in silos, with no capacity for dynamic adaptation.

Solution: interconnected, responsive systems

To overcome this rigidity, the company has opted for a more resilient approach, based on three levers:

Real-time sensors to detect changes in the environment (bin positions, zone occupancy, obstructed paths).

On-board logic in AMRs, capable of recalculating routes and re-prioritizing missions according to context.

A robotic orchestrator connected to the ERP system, acting as a control tower: it synchronizes logistics flows with production priorities, while controlling robot adaptability in real time.

Thanks to this distributed architecture, automated systems are no longer static: they continuously adjust to the vagaries of the field, while remaining aligned with operational objectives.

Forindustrial automation to function sustainably, it must be designed as a living system, capable of absorbing unforeseen events without interrupting the flow.

The integration of adaptive technologies - sensors, on-board intelligence, interoperable middleware - is becoming a prerequisite for automating complex industrial environments, where stability can never be taken for granted.

Challenge 2 - Integrate heterogeneous systems and interoperate with existing ones

Heterogeneity: a structural brake on automation industry

One of the most common pitfalls inindustrial automation projects concerns the cohabitation of old equipment and new technologies. Over the years, most industrial sites have accumulated an infrastructure made up of machines, PLCs and software of various generations, often incompatible with each other.

In this context, automation doesn't just mean adding sensors or robots: it also means ensuring seamless communication between existing systems and the latest technological building blocks.

Example: lack of dialogue between quality control and automated line

A food company wanted to automate quality control by integrating an intelligent camera on a packaging line. Problem: the conveyor, controlled by an old PLC, was unable to synchronize the stops required for visual inspection. Result: blurred image, undetected defects, loss of reliability.

Solution: an interoperability layer between OT and IT

To overcome this obstacle, the project team set up an OPC-UA/MQTT communication gateway, bridging the gap between the existing automation system and the new connected devices.

This approach has made it possible to :

Use PLC data without modifying the infrastructure.

Precisely synchronize conveyor stops with image capture.

Integrate this new brick into a coherent automation environment, without technological disruption.

Interoperability is an essential prerequisite for anyindustrial automation project. Without it, investments are fragmented, tools remain under-utilized, and the expected gains are never fully realized.

Challenge 3 - Exploiting and structuring data in a production environment

industrial automation can't work without data flow control

Sensors, supervision systems, connected machines: in Industry 4.0, every component generates massive volumes of data. But all too often, this data is siloed, not usable, or analyzed late. Efficient industrial automation therefore requires a data architecture designed for real-time performance and decision support.

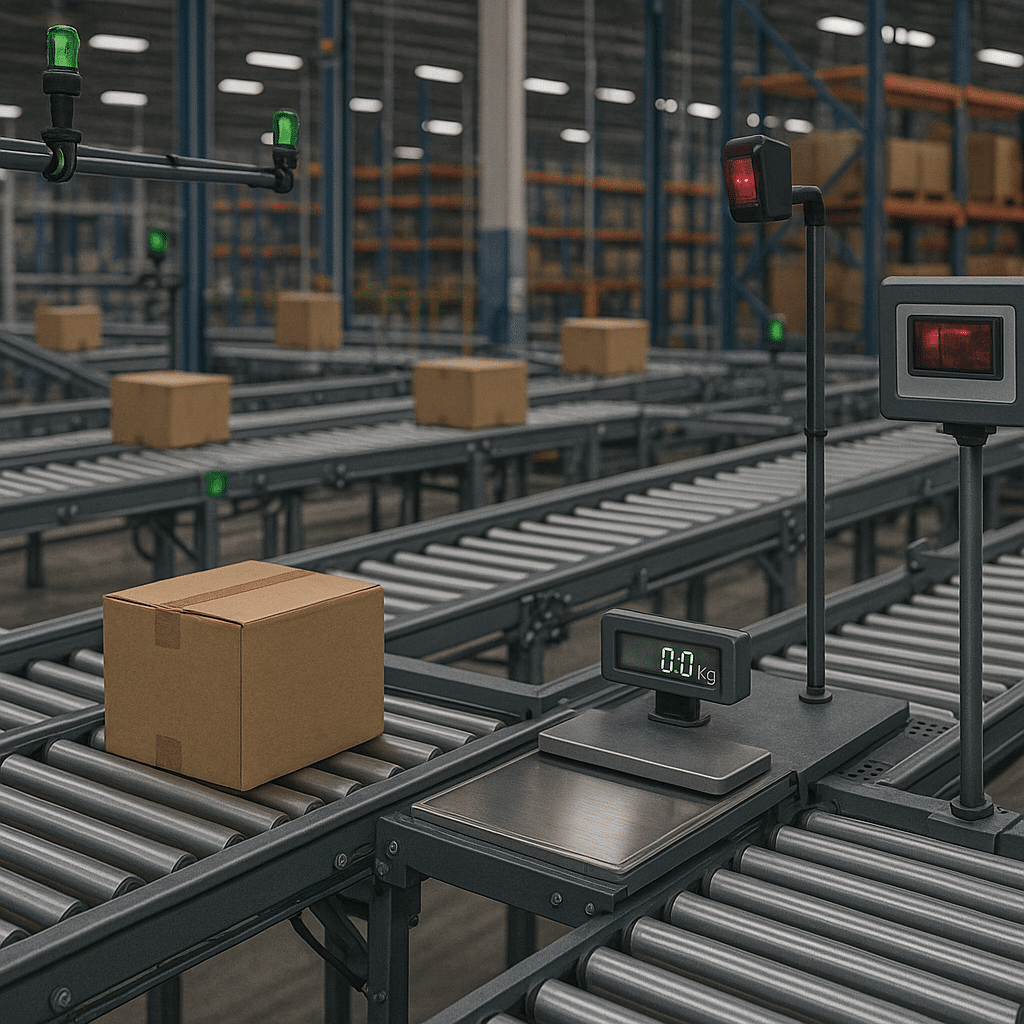

Example: a wealth of unused information in internal logistics

In a distribution warehouse for electronic components, conveyors, presence sensors, scales and scanners generated thousands of events every day. Yet there were no alerts to detect slowdowns or blockages. Control was done blindly.

Solution: edge computing and operational visualization

The implementation of a local processing system (edge computing) has made it possible to aggregate critical data (waiting time, weight, loading rate) for :

Detect anomalies in real time.

Display a dynamic dashboard for line managers.

Feed planning and predictive maintenance algorithms.

This approach has transformed dormant data into immediate levers for action, improving the responsiveness of the entire automated system.

When it comes toindustrial automation, data is a strategic asset. Its structuring, localized processing and clear restitution make the difference between passive automation and intelligent operations management.

Challenge 4 - Locate assets, machines and operators precisely

Indoor geolocation: an essential building block for frictionless automation

Many automated processes rely on the coordination of moving elements: robots, forklifts, temporary workstations, operators. In this context, industrial automation relies heavily on the ability to locate these elements in real time, with reliable precision. Without this, internal logistics become disorganized, systems grind to a halt, and lead times lengthen.

Example: confusion in the distribution of parts in the workshop

In an electronics assembly plant, the delivery AGVs were disoriented as soon as the stations were moved to meet a production emergency. Missions failed, and operators had to resume the flow manually.

Solution: integration of the Wheere indoor geolocation solution

To resolve these recurring malfunctions, the company deployed the indoor geolocation solution developed by Wheere.

Thanks to its precise, real-time location technology, Wheere has made it possible to :

Continuously locate workstations, AGVs and operators with technology adapted to industrial environments with high metal and movement density.

Automatically update delivery points used by automated systems, without manual intervention.

Smooth coordination between automated logistics and production, even during rapid reorganizations or operational emergencies.

The Wheere Cloud platform is interfaced directly with the WMS and the AGV control tool, enabling unified flow management and greater responsiveness across the entire chain.

To guarantee the performance of industrial automation in constantly changing environments, indoor geolocation must be considered as a basic infrastructure, just like industrial sensors or PLCs. It determines the fluidity of flows, the reliability of interactions between systems, and the ability of equipment to adapt in real time.

You may also be interested in this article:

10 technological innovations revolutionizing the industry

Challenge no. 5 - Supporting teams in industrial transformation

The human factor: the cornerstone of successful industrial automation

Even the most advanced systems remain dependent on their integration into the human organization. All too often,industrial automation projects fail not because of a technological flaw, but because of a lack of ownership by the teams. The human dimension is therefore central: training, communication, role adaptation and co-construction are the levers of success.

Example: rejecting a cobot on a production line

In a foundry, the introduction of a collaborative robotic arm was intended to relieve operators of a tedious task. However, due to a lack of explanation, the teams perceived it as a threat or a source of complication. As a result, the robot remained at a standstill, and tasks were carried out manually.

Solution: active training and co-design of flows

The project team reviewed its approach:

On-site training of operators in the use of the cobot.

Integrate their feedback into trajectory programming and work zone definition.

Valuing the human role in supervision and workstation optimization.

Within a few weeks, the robot was fully accepted, and its added value fully exploited.

A successfulindustrial automation strategy also means rethinking the role of employees, not as performers but as augmented players. People are not the obstacle: they are the keystone.

Did you like it?

Share it and discover other articles you might also like!

- Articles

- News

- News